Industrial Flooring and Stair Treads Designing and Installation

SGFS-01: Galvanized steel grating stair treads and flooring.

Flooring and stair treads are widely seen in the industrial applications for easy and safe working and operating. Here are the integral design and installation of industrial flooring and stair treads. In the topic, the flooring and stair treads commonly refer to the steel grating flooring and stair treads. Sometimes, the handrail infill meshes are also made by steel grating according to different applications and requirements. Browse the following topic and know more about the application. You can also send us your requirements and we will customize it for you.

Flooring requirements

The flooring is commonly made of steel grating, including galvanized steel grating, aluminum steel grating and stainless steel grating. In the general applications, the maximum opening within a platform or walkway shall not permit a 40 mm diameter sphere passing. And in the heavy duty applications, where people are working, as opposed to passing occasionally, the maximum openings shall not permit a 20 mm diameter sphere passing.

Where there is an access to machinery, any flooring provided shall be in accordance with BS EN ISO 14122-2: Safety of machinery Permanent means of access to machinery.

When the walkway is usually subject to passage or crossing of several persons simultaneously, the minimum unobstructed width shall be 1000 mm.

In all other cases, the minimum unobstructed width of a platform or walkway shall be 600 mm.

The minimum headroom above the top surface of a platform or walkway shall be 2100 mm.

Design loads and deflections

Design loads

Design loads should take plant, equipment or any other items placed on walkways, platforms into consideration. These items may implicate the design load. The loads should be designed to carry either the appropriate uniformly distributed load (UDL) or concentrated load, whichever produces the most onerous conditions of stress or deflection in the section.

Areas where a cut-out is required, the remaining area of the grating shall be able to carry the same load as the adjacent floor area.

Note:

Cut-out. Area where flooring has been removed to permit services, plant or structural members to pass through or to clear obstructions.

| Platform or Walkway Applications | UDL (kN/m2) |

Concentrated Load Over an Area of 300 mm × 300 mm (kN) |

|---|---|---|

| Occasional access | 1.5 | 1.0 |

| Light duty | 3.0 | 1.0 |

| General duty | 5.0 | 1.0 |

| Heavy duty | 7.5 | 1.0 |

Note:

|

||

Deflection

For pedestrian traffic, the deflection of a floor panel under the design load shall not exceed 10 mm or 1/200th of the span, whichever is the lesser. The difference in level between a loaded and a neighboring unloaded flooring shall not exceed 4 mm. See the technology page Calculate Principle of Material Capability in Safe Use to choose the suitable materials for safety use.

Clearances.

Any longitudinal ties between supports shall be at a level beneath the maximum permissible deflection of the underside of a loaded floor panel.

Fixings

Unless otherwise indicated by a risk assessment, platforms and walkways shall be fixed.

All panels should be fixed securely to the supporting structure using at least two fixings for each panel where they are connected together, or four fixings for each panel where they are not connected together.

Fixings should be used for all continuous span panels and for shaped panels where any side or edge of a panel might be subject to uplift as a result of a non-uniform imposed load. Whatever practicable, the fixings should be designed so that they can be fixed or removed by persons working from the surface of the secured panel. The projection of a fixing above the panel surface should be less than 4 mm.

Where clips are used, the minimum thickness should be appropriate for the design load.

Where applicable, precautions against corrosion should be taken.

When fixing bolts are used, their preferred minimum diameter should be appropriate for the design loads. They should be supplied with either a lock nut or a tab washer to retain the nut or have the fixing clip designed to retain the nut.

In areas where flooring deflections are at their extremes or where flooring is known to be subject to high levels of vibration, a more positive method of fixing should be used. Examples of this include the direct fixing or flooring to supports either by welding to or bolting through, their supports. Other methods of positive fixings recommended in lieu of friction grip fixing clips are drilling and tapping of supporting steelwork, welding studs or bosses to the supports, or driving studs into the supports using an appropriate tool.

Protective barriers

All platforms and walkways shall have protective barriers around all open sides, consisting of a handrail, at least one intermediate or knee rail, a toe plate and handrail standards.

The distance between two rails, or between the lower rail and the top of an upstand, shall be no more than 500 mm.

The top of the handrail shall be a minimum distance of 1100 mm above the top of the floor.

Lateral loads

Handrails shall be able to withstand the minimum lateral design loads given in Table 2.

| Use of Handrail | Load (kN/m) |

|---|---|

| Occasional access or light duty | 0.36 |

| General duty | 0.36 |

| Heavy duty | 0.74 |

| Areas subject to crowd loading, over 3 m wide | 3.00 |

- Occasional access. For inspection or maintenance by one person.

- Light duty. Regular one-way pedestrian traffic.

- General duty. Regular two-way pedestrian traffic.

- Heavy duty. High density pedestrian traffic.

Joints

Joints in continuous rails shall be positioned at points of minimum stress, and not more than 1500 mm from the center-line of a stanchion. They shall not be placed out-board of the end stanchions where there is a formed bend.

Stanchions

Stanchions shall not be mounted from toe plates, unless the toe plates are structural members.

Toe plate. Upstand on a walkway or landing, or the lower part of a guard-rail, to prevent feet or objects sliding off (also known as a kicking plate).

SGFS-02: Toe plate under the handrail of steel grating flooring.

SGFS-03: Toe plate on the cut out of steel grating flooring.

SGFS-04: Toe plate on the walkway.

SGFS-05: Toe plate on the steel grating stair treads.

Clear spaces

There shall be a clear space of at least 75 mm behind the top rail, to allow the rail to be used as a hand-rail.

Safety grates

Hazardous areas, such as the gap in handrails at the head of a ladder, shall be protected by a self-closing gates. This gate shall provide protection equal to that required for the surrounding guarding, i.e., consisting of a handrail, at least one intermediate or knee rail, a toe plate and a handrail standard it shall close gently but securely and be designed to swing only into the landing. Hold-open devices shall not be fitted.

Infill

Where additional protection is required (for example, machine guarding), non-combustible infill shall be provided.

The infill types can be welded steel grating, press locked steel grating, perforated metal mesh, welded wire mesh, expanded metal mesh and others. You can choose according to your requirements or tell us your requirements and we will recommend the suitable for you.

SGFS-06: Welded steel grating handrail infill mesh.

SGFS-07: Press locked steel grating handrail infill mesh.

SGFS-08: Welded wire mesh handrail infill mesh.

SGFS-09: Perforated metal mesh handrail.

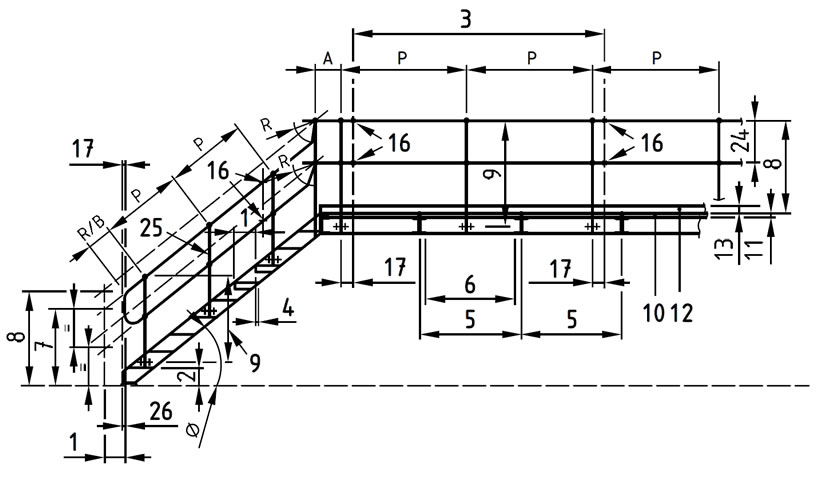

SGFS-10: Side view of flooring and stair treads drawing.

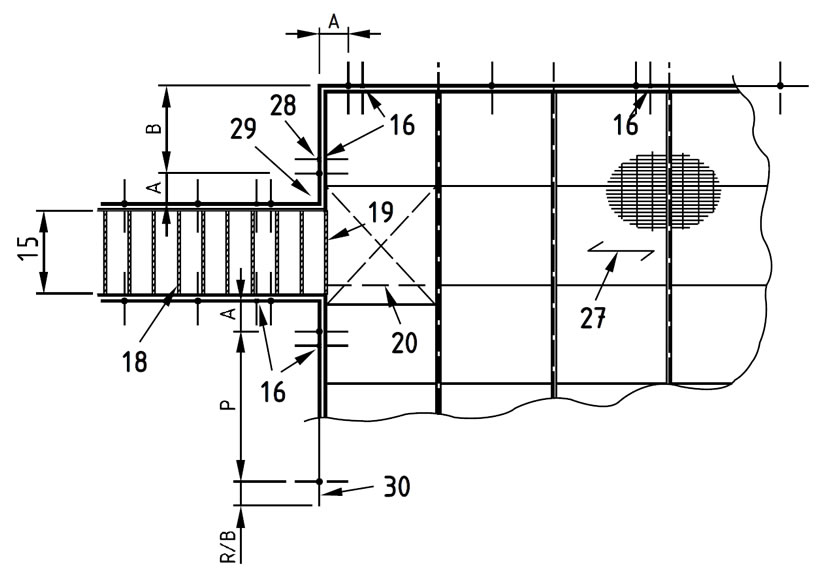

SGFS-11: Front view of stair tread and handrail infill.

SGFS-12: Top view of flooring and stair treads.

Key of typical arrangement of protective barriers in SGFS-10, SGFS-11 and SGFS-12.

1. Going.

2. Rise.

3. Distance between joints on continuous runs (2P minimum to 4P maximum).

4. Overlap.

5. Span.

6. Clear span between supports.

7. Distance from the pitch line to the center line of stair handrail (900 mm to 1000 mm).

8.design height (1100 mm above either the pitch line or the top of the floor).

9. Height of platform or stair standards, from the center line of the base plate fixing when using side palm bases as shown (or, where appropriate, from the underside of flat base) to the center line of handrail.

10. Floor.

11. Floor depth.

12. Toe plate.

13. Upstand on a toe plate

14. Stair width.

15. Tread length.

16. Joints in rail completed either by welding or by providing suitable internal connectors.

17. Location of the center line of a joint in rail from the center line of a standard which is 150 mm (max.). (for more rigid connections, especially at corners, avoid joints on the center line of a standard.)

18. Stair nosing.

19. Platform nosing.

20. Welded joint in floor sections to prevent a possible trip hazard at the head of a stair.

21. Mesh infill, where required to provide additional guarding.

22. Radius corner on mesh infill to suit the radius of a return bend in the rails.

23. Platform standard with either side palm bases as shown, or flat bases where appropriate.

24. Distance between center lines of rails, to suit max. 500 mm clear distance between rails.

25. Stair standard with either side palm bases as shown or flat bases where appropriate.

26. Dimension between 0 mm to 55 mm from the end of a stair string to the first tread.

27. Denotes the direction of span, for open bar grating when appropriate.

28. No more than one joint between standards at any corner.

29. No joints between standards at the top of a stair.

30. No joints before first standard.

31. Handrail.

32. Kneerail.

Toe plate

Where toe plates are an integral part of the flooring, the upstand shall be at least 100 mm in height above floor level. Any gap between the floor and the upstand shall not be grater than 20 mm.

Inclined flooring

Where inclined flooring exceeds 10°, additional traction shall be obtained by enhancing the slip resistance of the surface, e.g. By incorporating gripper bars or using serrated bearing bars on open bar gratings.

Two continuous handrails, one on each side of the walkway are particularly important on inclined walkways, as the user's momentum when descending some inclines, might not always be safely arrested by having only one handrail on one side.

Nosing

Where the edge of flooring forms a nosing, its slip resistance properties shall be at least equivalent to that of the nosing of the stair treads.

SGFS-13: Inclined steel grating floor.

SGFS-14: Gritted surface nosing on floor and stair tread edge.

Clearances

In order to prevent irregular undulation of flooring panels (with the exception of plate floors), there shall be a gap of at least 25 mm between the bottom of bearing bars and any secondary supports or longitudinal ties between primary supports.

Stair treads

The design of stair treads shall be such that, the tread shall deflect elastically by not more than 1/300th times its span, or 6 mm , whichever is the lesser.

Nosings

Where the edge of stair treads forms a nosing, its slip resistance properties shall be at least equivalent to that of the nosings of the stair treads.

SGFS-15: Tripped plate nosing.

SGFS-16: Chequer plate nosing.

SGFS-17: Plain plate nosing.

SGFS-18: Gritted plate nosing.

Slip resistance requirements

All surfaces shall be tested for slip potential in water wet conditions in accordance with technology page Determination of Industrial Floor Slip Resistance.

Under technology page, the slip resistance classifications are:

Unsuitable for wet conditions.

Slip resistant surface.

Enhanced slip resistant surfaces.

Surfaces that are classified as suitable for use in dry conditions only (as specified in technology page Determination of Industrial Floor Slip Resistance) shall only be used where the risk assessment indicates there is no possibility of contaminated surfaces.

Slip resistance.

Slip resistant flooring shall be used in all areas where the risk assessment indicates foreseeable water wet contamination.

Enhanced slip resistance

Enhanced slip resistance shall be required where strenuous activity (for example, pushing and pulling equipment) is routinely undertaken on floorings under water wet contamination.

Inclined floorings

The additional coefficient of friction (CoF) required for inclined floorings shall be determined by taking the tangent of the angle of the incline and adding that to the minimum CoF for each classification level.

Marking requirements

The following particulars shall be clearly marked on the delivery note, invoice or supplier's certificate provided with the consignment:

Name, trademark or other means of identification of the manufacturer.

The quantity and date of delivery.

Components shall be marked with a reference and/or location number to assist assembly on site.

Note: We can supply you one-stop purchase from us including steel grating floorings, steel grating stair treads, steel grating handrail infills and other components.