FRP Pultruded Grating - I or T Bearing Bars for High Load

FRP pultruded grating, also called GRP pultruded grating, is made of glass fiber and polyester resin surface similar to FRP molded grating. It adopts I or T bars as the bearing bars and round or shaped bars as connecting rod and assemble them together in a certain process. Compared with FRP molded grating, it can supply higher load capacity and high strength to weight ratio. It is ideal for installing places where exceptional loading bearing and uninterrupted spans needs to be bridged.

Surface of FRP pultruded grating.

- Smooth surface.

- Grit surface.

- Corrugated surface.

- Convex surface

FPG-01: Smooth surface.

FPG-02: Grit surface.

FPG-03: Convex surface.

FPG-04: Corrugated surface.

Bearing bar of FRP pultruded grating

- I bar.

- T bar.

- Heavy-load bar.

FPG-05: I bar FRP pultruded grating.

FPG-06: T bar FRP pultruded grating.

FPG-07: Heavy-load FRP pultruded grating.

Cross bar of FRP pultruded grating

- Round bar.

- Shaped bar.

FPG-08: Round bar FRP pultruded grating.

FPG-09: Shaped bar FRP pultruded grating.

Specifications of FRP pultruded grating

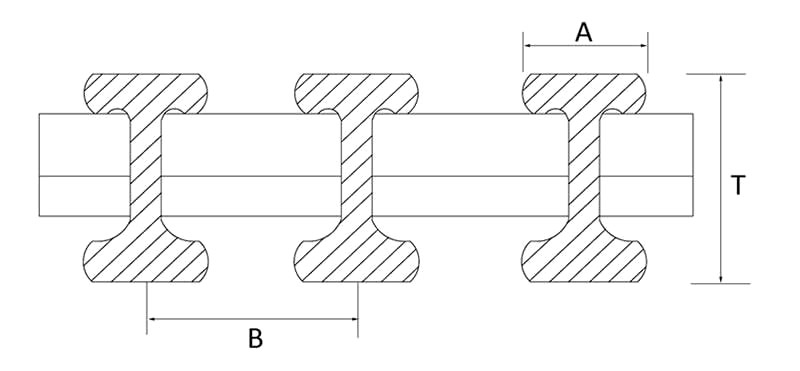

FPG-10: I bar FRP pultruded grating drawing.

| Item | Thickness T | Top Bar Width A | Bar Spacing B | Open Rate |

|---|---|---|---|---|

| FPGI-01 | 1" | 0.6" | 1.5" | 60% |

| FPGI-02 | 1" | 0.6" | 1.2" | 50% |

| FPGI-03 | 1" | 0.6" | 1.0" | 40% |

| FPGI-04 | 1.2" | 0.6" | 1.5" | 60% |

| FPGI-05 | 1.2" | 0.6" | 1.2" | 50% |

| FPGI-06 | 1.2" | 0.6" | 1.0" | 40% |

| FPGI-07 | 1.25" | 0.6" | 1.5" | 60% |

| FPGI-08 | 1.25" | 0.6" | 1.2" | 50% |

| FPGI-09 | 1.25" | 0.6" | 1.0" | 40% |

| FPGI-10 | 1.5" | 0.6" | 1.5" | 60% |

| FPGI-11 | 1.5" | 0.6" | 1.0" | 40% |

| FPGI-12 | 2" | 0.6" | 1.5" | 60% |

| FPGI-13 | 2" | 0.6" | 1.2" | 50% |

| FPGI-14 | 2" | 0.6" | 1.0" | 40% |

FPG-11: T bar FRP pultruded grating drawing.

| Item | Thickness T | Top Bar Width A | Bar Spacing B | Open Rate |

|---|---|---|---|---|

| FPGT-01 | 1" | 1.5" | 2.4" | 38% |

| FPGT-02 | 1" | 1.5" | 2" | 25% |

| FPGT-03 | 1" | 1.5" | 1.8" | 18% |

| FPGT-04 | 1" | 1.5" | 1.7" | 12% |

| FPGT-05 | 1.5" | 1.5" | 2.4" | 38% |

| FPGT-06 | 1.5" | 1.5" | 2" | 25% |

| FPGT-07 | 1.5" | 1.5" | 1.7" | 12% |

| FPGT-08 | 2" | 1" | 2" | 50% |

| FPGT-09 | 2" | 1" | 1.5" | 33% |

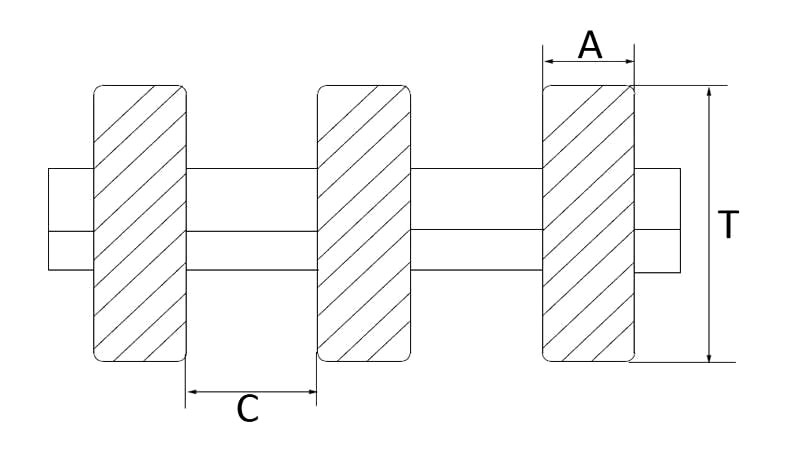

FPG-12: Heavy load FRP pultruded grating drawing.

| Item | Thickness T | Top Bar Width A | Clearance Width C | Open Rate |

|---|---|---|---|---|

| FPGH-01 | 2" | 0.6" | 0.9" | 60% |

| FPGH-02 | 2" | 0.6" | 0.6" | 50% |

| FPGH-03 | 2" | 0.6" | 0.4" | 40% |

Advantages of FRP pultruded grating

- Super strength. The FRP pultruded grating has high loading capacity to withstand the heavy duty applications.

- Lightweight. It is much lighter structure than the steel grating and FRP molded grating.

- Anti-slip performance. Grit, convex, corrugated surface supply excellent slip resistance performance for people's security.

- Corrosion resistance. The FRP pultruded grating has excellent chemical and physical corrosion resistance. It will never corrode during its long service life.

- Flame retardant. Same as the FRP molded grating, the pultruded grating have a flame spread rating of 25 or less, as tested in accordance with ASTM E-84 and meets the self-extinguishing requirements of ASTM D-635.

- Maintenance free. The FRP pultruded grating has excellent self-cleaning performance. It needs little maintenance during using period.

- High strength to weight ratio. Less than half the weight of steel grating, allowing easy installing and replacing.

- UV protection. The polyester resin surface has excellent UV resistance protection. It can protect FRP pultruded grating from UV rays and extend the service life of grating.

Functions of FRP pultruded grating

- Platform.

- Walkway.

- Catwalk.

- Trench cover.

- Offshore oil platform.

- Stair treads.

- Security fence.

- Boat deck.

- Inspection trench cover.

- Transformer grating.

Suitable fields of FRP pultruded grating

- Water treatment.

- Chemical plants.

- Oil industry.

- Textile factory.

- Power plants.

- Transportation industry.

- Pulp and processing plants.

- Car wash shop.

- 4S store.

- Municipal engineering.

FPG-13: FRP pultruded gratings are used as stair treads.

FPG-14: FRP pultruded gratings are used as walkways.

FPG-15: FRP pultruded grating is used as drainage trench cover in car wash shop.

FPG-16: FRP pultruded grating is used as working platform.

FPG-17: FRP pultruded grating is used as transformer gratings.

FPG-18: FRP pultruded grating is used as inspection trench cover.