Different Steel Grating Structures Used for Special Fields

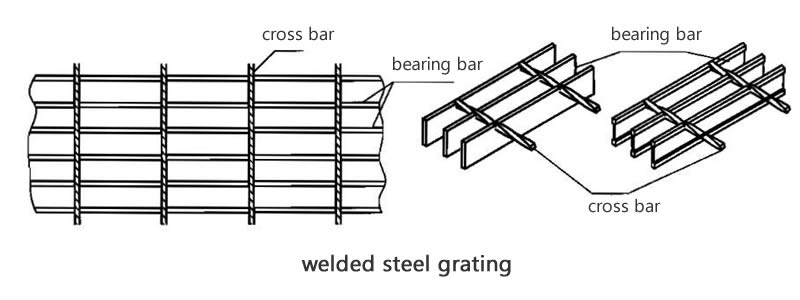

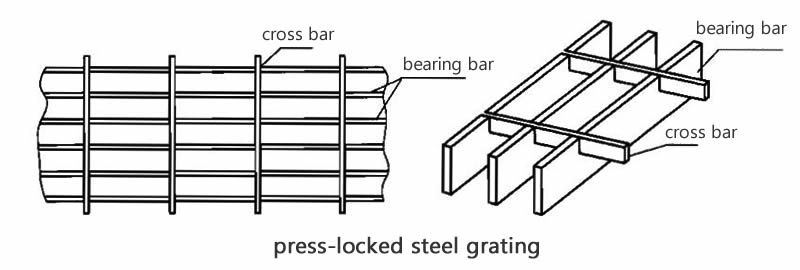

The steel gratings have two kinds of structures, welded steel grating and press-locked steel grating. The two structures have their own features.

The welded steel grating.

On the intersection points of the bearing bar and the cross bar, we weld with the pressure resistance welding. The cross bar of the welded steel grating is the twist square steel.

The welded steel grating is welded by the press resistance welding.

The press-locked steel grating.

On the intersection points of the bearing bar and the cross bar, we press the cross bar to the bearing bar with pressure. Or we could install the cross bar on the groove of the bearing bar. The steel grating that could reinforce the grating is called the press-locked steel grating. We use the cross bar as the flat steel.

The press locked grating is installed with the groove on the bearing bar, and we put the cross bar on the groove.

The steel grating design.

- The size and the shape for the steel grating could be designed according to the needs of the clients.

- The bearing pitch and the cross pitch could be designed according to the needs of the clients.

- On the end of the bearing bar we should use the flat bar whose standard is as the same as the bearing bar to wrap. We could also wrap for the steel grating with shape steel. We could wrap with skirtboard and the section of the end board should no be more than the section of the bearing bar.

- There could be not end board according to the needs.

- For the end board, the welding height should not be less than the thickness of the bearing bar. The welding length should not be less than the four times of the bearing bar.

- When the end board does not bear the loads. We could weld for the bearing bar every 4 bars and the distance should not be more than 150 mm.

- When the end board bears the loads we should not weld alternately.

- When the end board is on the same direction of the bearing bar we should weld for every cross bar.

- When the cut out and the holes is more than 180 mm we should wrap for the steel grating.

- We should weld totally for the stairs treads end board.

- When there is leading edge protection board it should be through the whole steps.

- The bearing bar could be rectangular, I shape steel grating and other geometry shape steel.

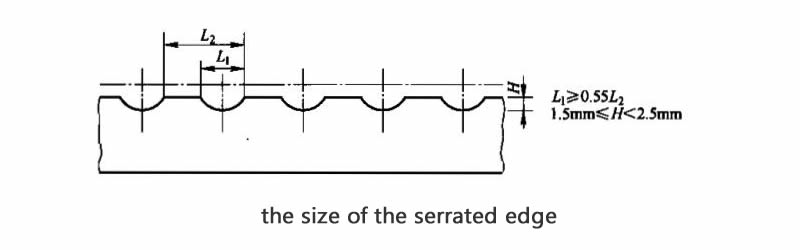

- The bearing bar could be with the serrated steel grating. Thus it has the good ability to anti-slip. There should be more than five serrated designs every 100 mm.

The serrated edge on the steel grating could increase the slipping resistance.