Specifications, Types and Requirements for Metal Open Bar Grating

Metal open bar grating, also called steel grating, steel bar grating, is a type of solid grating widely used in the industrial applications as flooring and stair treads. It has anti-corrosion material, multi-type and anti-slip surface to help secure workers safe and reduce accidents happening.

Here are several definitions, specifications and requirements of metal open bar grating used in the industrial flooring and stair treads.

Definition

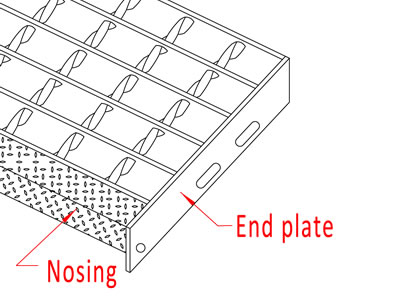

- End plate. Plate fixed to stair tread for attachment to a string.

- Curb angle. Support fixed to concrete or steelwork (vertical leg up) around perimeter of flooring to provide a toe plate.

- Bars.

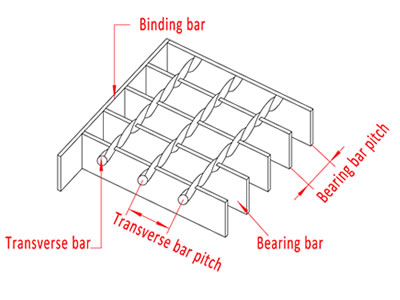

- Bearing bars. Member that carries the load between supports.

- Transverse bar. Member fixed at right angles to bearing bars to provide lateral restraint.

- Pressed bar. Member fixed diagonally between adjacent bearing bars to provide lateral restraint.

- Binding bar. Member or section fixed to the edge of a grating, flush with the top of the bearing bar.

- Nosing. Member attached to the front edge of a stair tread or to a grating at the head of a stair.

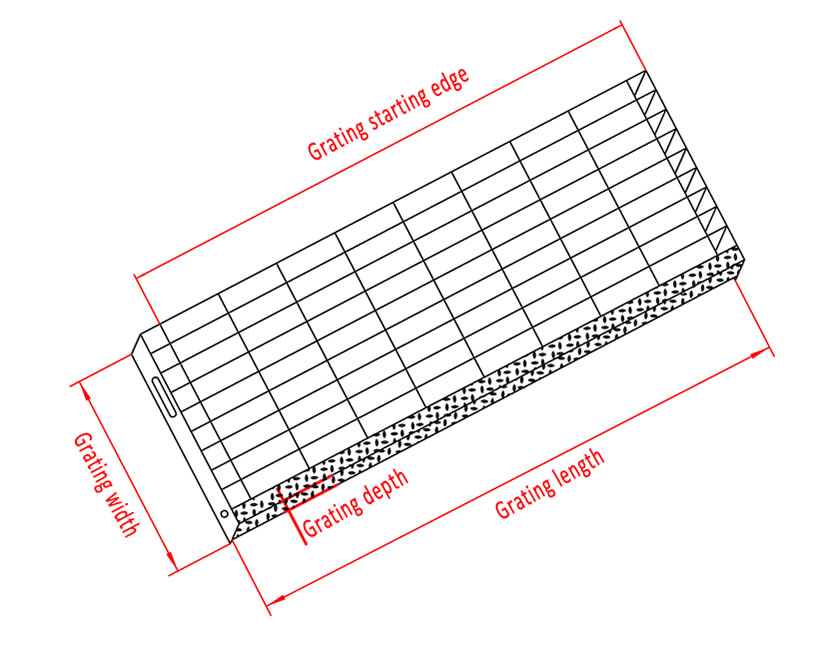

- Dimensions of gratings.

- Grating length. Overall measurement in a direction parallel to the bearing bars.

- Grating width. Overall measurement in a direction at right angles to the bearing bars.

- Grating depth. Overall depth of grating, which is usually the depth of the bearing bar.

- Grating starting edge. Distance from center of first transverse bar to end of grating.

- Pitch

- Bearing bar pitch. Distance center-to-center of bearing bars.

- Transverse bar pitch. Distance center-to-center of transverse bars.

- Pressed bar pitch. Distance in a longitudinal direction between points of lateral resistant to adjacent bearing bars.

- Serration pitch. Distance center-to-center of the repeat pattern.

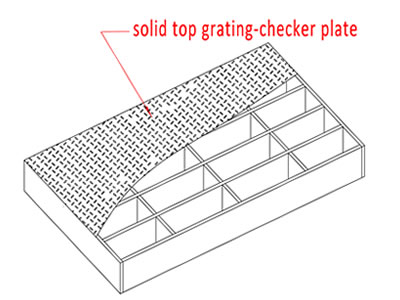

- Solid top grating. Open mesh grating to which a steel plate is welded to the top surface during manufacture.

- Resistance welding. Method whereby heat is generated at the metal intersection points by an electric current and, as the foraging temperature is reached, pressure is applied and the materials are gorge-welded together.

Material requirements

- Steel.

- Stainless steel.

- Aluminum

Protection against corrosion

Anti-corrosion requirements should be according to the application environments and customers' requirements.

Main corrosion resistance method.

- Surface treatment.

- Low carbon steel + hot dipped galvanized.

- Low carbon steel + PVC coating.

- Anti-corrosion steel.

- Aluminum steel.

- Stainless steel.

Anti-slip protection

To improve anti-slip performance of metal open bar and reduce safety accident, several method can be adopt and reach an agreement with customers.

- Serrated surface. The serrated surface can increase the friction of metal open bar grating, and reduce people from slipping.

- Nosing. On the stair treads, the nosing should be continuously installed to prevent people from slipping down.

- Solid steel plate. Solid steel plate, (commonly is ) can be welded to the top surface during manufacture to increase the friction of steel grating. Besides it can increase the strength of the floor and provide a more suitable surface for the passage of small solid wheeled trolleys when required.

Metal open bar grating and chequer bar surface.

Metal open bar grating and chequer plate nosing.

Size requirements

All the products are produced under the standard and within the permissible tolerance.

- Tolerance requirements.

- The maximum permissible tolerances from finished sizes of gratings shall be as shown in Table 1.

- The maximum permissible manufacturing tolerances shall be as given in Table 2.

- For detailed specification.

- For serrations.

- The serration length shall be not less than 55% their pitch and serration depth shall be not less than 2.5 mm. There shall be at least five serrations per 100 mm length of grating. Serrations shall be punched out of plain bar tops in order to provide cut edge for increased grip.

| Location | Tolerance (mm) |

|---|---|

| Length of grating panel or individual bearing bar | +0/-5 |

| Width of grating | +0/-5 |

| Depth of bearing bars | |

| Up to and including 25 mm | +1/-0.5 |

| Over 25 mm up to 50 mm | +1.5/-0.75 |

| Over 50 mm up to 100 mm | +2.0/-1.0 |

| Over 100 up to 150 | +2.0/-1.5 |

| Thickness of bearing bar | |

| Up to 10 mm | ±0.4 |

| Over 10 mm up to 15 mm | ±0.5 |

| Binding | |

| Top of binding bar above bearing bar | +4.0/-0 |

| Underside of binding bar above bottom of bearing bar | +0 |

| Location | Tolerance (mm) |

|---|---|

| Difference between the length of diaonals | 5 (out of squareness of grating panel) |

| Transverse bars in either direction from perpendicular alignment with bearing bars | 1:100 |

| Transverse bar spacing | ±5 per 1500 length of bearing bars |

| Bearing bar lean | 1:10 |

| Transverse bow of panel before fastening to supports | 1:100 |

| Longitudinal bow of panel before fastening to supports | 1:200 |

Construction requirements

- Bearing bars shall be provided with lateral restraint by means of transverse bars or pressed bars, fixed at each point of intersection or contact with the bearing bars by means of welding, riveting or pressure lock.

- Welding of steel shall either be arc welding or resistance welding.

- Where binding bars are loadbearing, they shall be of equivalent strength to the bearing bars but not project below them.

- Where the function of binding bars excludes load transfer, they shall be attached to the bearing bars by such means as that they can be demonstrated if required, by calculation or test, to be fit for the purpose for which they are intended.

However, where the binding bars are subject to load transfer from bearing bars, including end plates for stair treads, the connection between them shall be provided, if welded, by a fillet weld.. The fillet weld shall have a leg length that is at least equivalent to the thickness of a bearing bar, throughout the depth of the connection on one side of every bearing bar. - When binding bars are applied along the length of a grating, they shall be secured at every transverse bar, or at every point where they are in contact with a pressed bar.

- Cut out.

- Where a cut-out is required in a grating and the gap is less than 30 mm, the opening shall be trimmed with a binding bar.

- Where a cut-out is required in a grating end and the gap is greater than 30 mm, the opening shall be trimmed with a toe plate.

- Nosing shall be used consistently throughout the stair.

Cut-out gap less than 30 mm, the opening shall be trimmed with a binding bar

Cut-out grater than 30 mm, the opening shall be trimmed with a toe plate.

Performance requirements

Gratings.

- Metal open bar gratings shall withstand the appropriate loads the customers' required.

- Metal open bar gratings required to take vehicle loads travelling at 90° to the direction of bearing bars, i.e. Across the bearing bars, shall either have pressed bars, or transverse bars that pass through the bearing bars below the top of the grating.

Fixing dimensions for tread end plate.

Key

1. Leading edge of stair tread fitted with anti-slip nosing.

2. Pitch line.

3. Riser.

4. Going.

5. Overlap (≥ 16 mm).

6. Tread width.

7. Overall depth of endplate (70 mm).

8. Dimension from top of endplate to center bolts (50 mm).

9. Dimension from leading edge of tread to center of first bolt (30 mm).

10. Bolts center dimension.

11. Hole center for dimension from slotted hole (30 mm).

12. Dimension for slot width (14 mm for stair treads, 12 mm for ladder treads).

13. Hole diameter for first bolt (14 mm for stair treads, 12 mm for ladder treads)

Note:

- Bolt center dimension for tread widths of of 250 mm to 290 mm is 125 mm.

- Bolt center dimension for tread width of 291 mm or more is 175 mm.