Comparison in Four Steel Grating Projects for the Grain Depots

Heavy loads steel gating could bear much loads and it's welcome for the factories platform.

Recently years, the steel grating is widely used on factories, workshops, mines, ports, docks and grain depots. For these places the steel grating not only should consider the safety for people but also should meet the needs that other cars ride on the places. The steel grating should have enough loads to support the necessary weight, thus we should design for the special occasion.

The engineering.

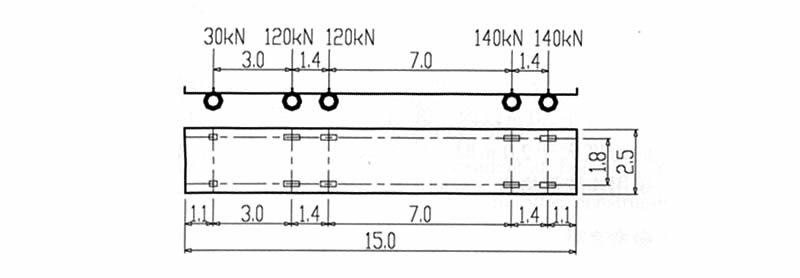

For the grain depots, there is steel grating on the top of the stockpile. The size for the grain depot is 3.8 m × 4.0 m, the floor plan and the section is like the drawing. The span is big because the steel grating is put on the grain depot directly. We should put the secondary beam on the grain depot to decrease the span. The project one, we should put one secondary beam transversely. The project two, we should put two secondary beams transversely. The project three, we should put one secondary beam lengthwise. The project four, we should put secondary beams lengthwise. The size of the steel grating for the project one and the project three is 130 mm × 10 mm × 50 mm. We weld the bearing bar and the cross bar with the pressure resistance welding. The size of the steel grating for the project two and the project four is 110 mm × 8 mm × 50 mm. And the bearing bar is welded with the cross bar with the pressure resistance welding.

The secondary beam is to increase the loads for the steel grating and reinforce the structure.

The bearing capacity.

The loads.The loads.

The elevation and the plan drawing show the size of the car loads. According to the following table, we can calculate that the maximum for the car loads is 98 kN.

According to the car loads we can arrange the steel grating.

| The project | The technology index (kN) | The project | The technology index (m) |

|---|---|---|---|

| The standard for the car loads | 550 | The tread | 1.8 |

| The standard weight for the front axle | 30 | The width and the length for the front wheel | 0.06 |

| The standard weight for the middle axle | 240 | The width and the length for the middle and the back wheel | 0.12 |

| The standard weight for the back axle | 280 | The size for the car | 37.5 |

| The wheelbase | 12.8 | – | – |

The steel grating arrangement.

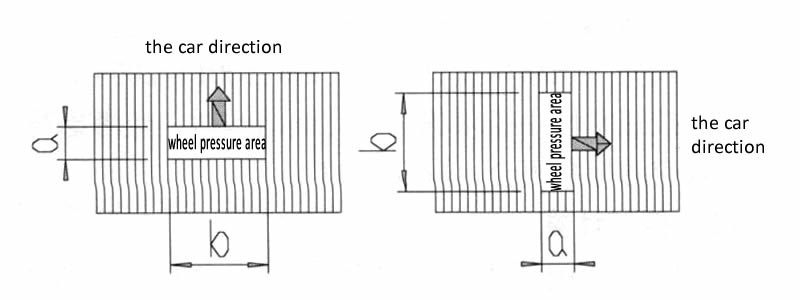

According to the car direction, we could classify the steel grating by crossing gully steel grating and side gully steel grating. The crossing gully steel grating is that the bearing bar is parallel with the car direction. The side gully steel grating is that the bearing bar is vertical to the car direction.

The different usages for the steel grating are used for certain fields.

The strength of the steel grating.

According to the table, we could find that the stress of the steel grating project one is 172.5 N/mm2 and it's the 53% of the project three. The stress of the steel grating project two is 194.9 N/mm2 and it's the 57% of the project four. The bearing loads of the project three and project four could not meet the needs. To meet the needs, the specification of the steel grating should be 150 mm × 12 mm × 50 mm or 130 mm × 10 mm × 50 mm. The crossing gully steel grating could bear more loads than the side gully steel grating.

| Project 1 | Project 2 | Project 3 | Project 4 | |

|---|---|---|---|---|

| The permissible stress [σ] | 215 | 215 | 215 | 215 |

| The practical stress (σ) | 172.5 | 194.9 | 326.2 | 341.7 |

| σ/[σ] | 80% | 90% | 152% | 159% |

The deflection.

The steel grating should meet the demands of the strength and we should calculate its deflection. For the heavy steel grating, the deflection should not be more than the 1/500 of the span.

| Project 1 | Project 2 | Project 3 | Project 4 | |

|---|---|---|---|---|

| The permissible deflection [D] | 3.6 | 2.4 | 3.6 | 2.4 |

| The practical deflection (D) | 2.6. | 1.6 | 7.5 | 4.3 |

| D/[D] | 72% | 67% | 208% | 179% |

The deflection for the project one is 2.6 mm, it's the 72% of the permissible deflection. The bearing bar deflection for the project four is 4.3 mm and it's the 179% of the permissible deflection. To meet the design needs, the specification of the steel grating should be 130 mm × 10 mm × 50 mm. So the span of the crossing gully steel grating should be less than 1.5 m.

The structure design.

- The specification of the bearing bar should be as the same as the end bar. The section area of the end bar should be more than the section of the bearing bar.

- The end bar is the one-side fillet welding and the height is more than the bearing thickness. The welded length should be more than the 4 times of the bearing bar thickness.

- On the condition that the end bar does not bear the loads, we weld the bearing bars every four bars. The bearing bar pitch should not be more than 150 mm. When there is loads on the bearing bar we should not weld the bar with interval.

- When the end bar is on the same direction with the bearing bar, the end bar should connect with the cross bar. The section of the cross bar should not be less than 20 mm2.

After the test, we could get the following conclusions. The bearing loads for the cross gully steel grating is better than the side gully steel grating. If the span and the loads are the same we should use the cross gully steel grating. The span for the heavy steel grating should not be big and the span should be with 2.0 m. If there is the special design and the span of the steel grating is more than 2.0 m, we should use the other measures. We could install the steel grating continuously and install the steel grating bilaterally.