Covered FRP Grating – Molded or Pultruded Grating for Durable Life

Covered FRP grating is a type of anti-slip covered grating, which is combination the slip resistance floor plate and FRP grating. The FRP grating can be molded FRP grating or pultruded FRP grating. The covered FRP grating supplies 30% higher stiffness than the molded or pultruded FRP grating. It is widely used for pedestrian or cart traffic passing in chemical, sewage treatment plants, coal mine and other industries as walkway, platform and stair treads.

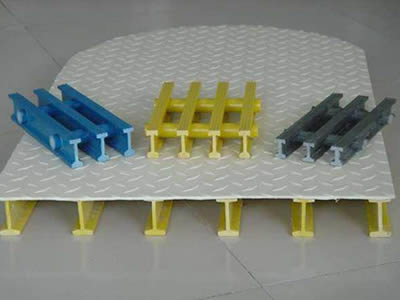

Grating type of covered FRP grating

- Molded FRP grating combined with floor plate.

- Pultruded FRP grating combined with floor plate.

CFG-01: Molded covered FRP grating.

CFG-02: Pultruded covered FRP grating.

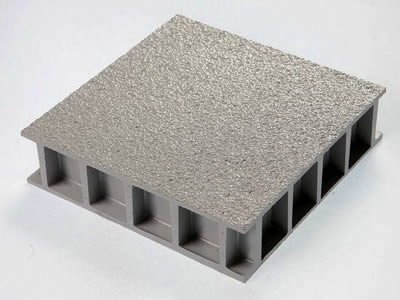

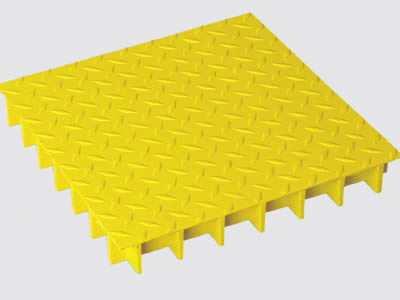

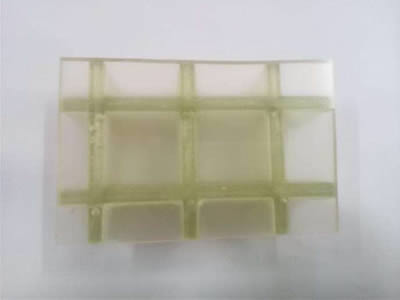

Surface type of covered FRP grating.

- Smooth surface.

- Concave surface.

- Grit surface.

- Checker plate surface.

CFG-03: Polished surface.

CFG-04: Concave surface.

CFG-05: Gritted surface.

CFG-06: Checker plate surface.

Advantages of covered FRP grating

- Corrosion resistance. Like almost all the FRP products, the covered FRP grating will not corrosion or rust during its long service life.

- Slip resistance. Concave, grit and checker plate surface supplies excellent slip resistance performance. It ca protect pedestrian and vehicles safety when passing through the grating.

- Extremely long service life. With excellent corrosion and rust resistance performance and high strength, the FRP grating can play an good performance up to 30 years.

- Solid top. The solid FRP plate has excellent impact resistance and high load capacity to bear the heavy duty vehicles and loads.

- Transparency choice. The covered FRP grating can be made into transparent, translucent and opaque through changing the color pigment content.

- Customized drainage position. In some applications and places, it should be designed with drainage exit, just tell us we will customize it according to customers' requirements.

- Different checker plate pattern. There are willow leaf, lentil diamond or other customized patterns to supply better anti-slip performance and suit more applications. Additional, it can make the checker plate covered FRP grating more beautiful and attractive.

- Handles added. Handles can be added according to customers' requirements for easy lifting and taking down.

- More Benefit. More benefit of FRP grating or products, refer to the technology page Benefit of FRP Grating.

CFG-07: Lentil diamond pattern covered FRP grating.

CFG-08: Willow leaf pattern covered FRP grating.

CFG-09: Drainage exit for easy and convenient drainage.

CFG-10: Transparent FRP grating for choice.

CFG-11: Covered FRP grating with plastic handle.

CFG-12: Covered FRP grating with metal handle.

| Item | Mesh Size (mm) |

Thickness (mm) |

Panel Size (mm) |

Unit Weight (kg/m2) |

|---|---|---|---|---|

| CFGS-01 | 38 × 38 | 3 | 1220 × 3660 | 5.8 |

| CFGS-02 | 20 × 20 | 14 | 1247 × 4007 | 11 |

| CFGS-03 | 38 × 38 | 16 | 1220 × 3669 | 8.3 |

| CFGS-04 | 50 × 50 | 16 | 1960 × 1900 | 6.5 |

| CFGS-05 | 38 × 38 | 25 | 1220 × 3660 | 12.3 |

| CFGS-06 | 19 × 19 | 25 | 1220 × 3660 | 16.8 |

| CFGS-07 | 40 × 40 | 25 | 1000 × 4000 | 12.3 |

| CFGS-08 | 100 × 25 | 25 | 1007 × 3007 | 13.8 |

| CFGS-09 | 50 × 50 | 25 | 1220 × 3660 | 11.5 |

| CFGS-10 | 8 × 8 | 30 | 1527 × 4047 | 22 |

| CFGS-11 | 40 × 40 | 30 | 1000 × 4000 | 14.8 |

| CFGS-12 | 20 × 20 | 30 | 1000 × 4000 | 18 |

| CFGS-13 | 38 × 38 | 30 | 1220 × 3660 | 14.7 |

| CFGS-14 | 8 × 8 | 38 | 1527 × 4047 | 27 |

| CFGS-15 | 100 × 25 | 38 | 1220 × 3660 | 22.5 |

| CFGS-16 | 25 × 50 | 38 | 1220 × 3660 | 31 |

| CFGS-17 | 20 × 20 | 38 | 1247 × 4047 | 22.7 |

| CFGS-18 | 20 × 20 | 38 | 1000 × 4000 | 22.5 |

| CFGS-19 | 40 × 40 | 38 | 1000 × 4000 | 33.5 |

| CFGS-20 | 38 × 38 | 38 | 1220 × 3660 | 19 |

| CFGS-21 | 38 × 38 | 38 | 1525 × 3966 | 19 |

| CFGS-22 | 40 × 40 | 40 | 1000 × 4000 | 19.5 |

| CFGS-23 | 50 × 50 | 40 | 1220 × 3660 | 17 |

| CFGS-24 | 38 × 38 | 42 | 1220 × 3660 | 20.8 |

| CFGS-25 | 50 × 50 | 50 | 1220 × 3660 | 22.4 |

‘

Applications of covered FRP grating

- Walkway.

- Platform.

- Drainage cover.

- Working station.

- Transformer grating.

- Inspection well cover.

- Machine protection grating.

CFG-13: Covered FRP grating is used as walkway in factory.

CFG-14: Covered FRP grating is used as pedestrian way on the street.

CFG-15: Covered FRP grating is used as drainage cover.

CFG-16: Covered FRP grating is used as inspection well cover.

CFG-17: Covered FRP grating is used as working platform.

CFG-18: Covered FRP grating is used for protecting machines and pipelines.